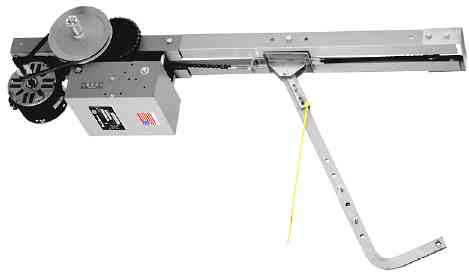

Sectional Door Operator

MODEL "MT"

Supply Powermaster Model “MT” Drawbar Operator(s)

Rated 1/2 hp, 115 volts, single phase, for use on standard lift sectional doors. motor shall be instantly reversible, permanent split capacitor type, protected from overload by a current sensing or thermal type overload device. Primary speed reduction shall be by means of an industrial duty v belt. Secondary reduction shall be by heavy duty chain and sprockets. an adjustable torque limiting clutch shall be provided to prevent overloading of operator. all shafts shall be a minimum of ¾” diameter and shall be supported by bronze bushings. a disconnect arm shall be provided for manual operation of door.

Control of the operator shall be by a class ii, 24 volt powered circuit, consisting of solid-state control board, transformer and limit switches.

All components of control system shall be ul recognized. electrical components shall be installed in a nema 1 enclosure.

A transformer shall be provided to reduce control voltage to 24 vac maximum. terminal strips shall be provided for connection of power supply line and all control devices. operator shall be wired for connection of a radio control, push button station and an obstruction sensing device without additional wiring modifications.

Control circuit shall provide instant reverse motor wiring. positive chain driven, rotary type limit switches shall be provided to limit full open and close travel of door. limit switches shall not be affected by removal of motor or by manual operation of door.

- 1/2 HP, 115V, 1Ø Only

- Instant Reversing Motor

- 24 VAC Control Circuit

- 3 Button, NEMA 1 Control Station Included

- Pre-wired for Radio Control, 3 Button Station, 1 Button Station, Automatic Reversing Equipment, Automatic Closing Time, and all Types of Access Control Equipment

- For Use on Strandard Lift Sectional Doors Operating up to 10 Cycles/Hour

- Backroom Requirements: Door Height plus 4'-6"

- Minimum Clearance Over Door: 3"

- Quick Release Door Arm Permitting Manual Operation

- Heavy Duty V-Belt and Chain Reduction

- Heavy Duty #48 Roller Chain Drive (Included)

- Adjustable Torque Limiting Clutch

MODEL "GT"

Supply Powermaster Model “GT” Drawbar Operator(s)

Rated ____ Hp, ____ Volts, ____ Phase, for use on standard lift sectional doors. primary speed reduction shall be by means of an industrial gear box with bronze worm gear in an oil bath. Motor shall be of the high starting torque, continuous duty industrial type, protected from overload by a current sensing or thermal type overload device.

- Motor controller shall be a heavy duty, full voltage. across-the-line, magnetic reversing contactor, that is mechanically and electrically interlocked.

- Electrical components shall be installed in a nema 1 enclosure. a transformer shall be provided to reduce control voltage to 24 vac maximum.

- Separate terminal strips shall be provided for connection of power supply line and all control devices. operator shall be wired for connection of a radio control, push button station and an obstruction sensing device without additional wiring modifications.

- Control circuit shall provide instant reverse motor wiring.

- Positive chain driven, rotary type limit switches shall be provided to limit full open and close travel of door.

- Limit switches shall not be affected by removal of motor or by manual operation of door.

- An adjustable torque limiting clutch shall be provided to prevent overloading of operator.

- A spring set, solenoid released brake shall be provided as standard.

- The final reduction and drive shall be a heavy duty #41 roller chain and sprockets.

- The drive shaft shall be supported by ball bearings and be a minimum of 3/4” in diameter

MODEL "APT"

- For use on Sectional Doors requiring high cycles and quiet operation

- Solid State Circuitry with Instant Reversing Motor Wiring

- 3 Button NEMA 1 Control Station Included

- Heavy Duty #65 Roller Chain Included

- Adjustable Torque Limiting Clutch

- Positive Chain Driven Rotary Limit Switches

- Drawbar Disconnect (For Manual Operation in case of power failure)

- Baked on Grey Powder Coat Finish

- Optional remote mountable warning light module with dual function timer and Red and Green lights

- 24 VAC Control Circuit Pre-wired to accept Radio Control, 3 Button Station, 1 Button Station, Automatic Reversing Equipment, Automatic Closing Timer, and All Types of Access Control Equipment

- 115 VAC Resilient Mount PSC Motor with Full Overload Protection

- Solid State Circuitry with Power and Program Feedback LED’s

- On Board Open/Close/Stop buttons for service and adjustments

- Terminals labeled and grouped by function

- Auto-Detect monitored photo beam for simplified installation

- Field adjustable built in functions including: timer to close, mid-stop, delay on reverse, lock bar sensing, maximum run time, etc.

- Optional remote mountable warning light module with dual function timer and Red and Green lights

- For Use on Sectional Doors Requiring High Cycles and Quiet Operation

- Heavy Duty V-Belt and Chain Reduction, Mechanically Self Locking

- Heavy Duty #65 Roller Chain Included

- Adjustable Torque Limiting Clutch

- Positive Chain Driven Rotary Limit Switches

- Drawbar Disconnect (For Manual Operation in case of power failure)

- Baked on Grey Powder Coat finish

MODEL "GSL"

- High Starting Torque Motor with Full Overload Protection

- Solid State Circuitry with Power and Program Feedback LED’s

- On Board Open/Close/Stop buttons for service and adjustments

- Terminals labeled and grouped by function

- Auto-Detect monitored photo beam for simplified installation

- Selectable Operating modes B2, C2, D1, E2, T, TS

- Field adjustable built in functions including: timer to close, mid-stop, delay on reverse, lock bar sensing, maximum run time, etc

- For Use on Sliding Doors

- Heavy Duty Worm Gear Reduction and Solenoid Brake

- Heavy Duty #41 Roller Chain Included

- Adjustable Torque Limiting Clutch

- Positive Chain Driven Rotary Limit Switches

- Manual Disconnect Arm for Operation of the Door in case of power failure

- Baked on Grey Powder Coat finish

MODEL "SL"

- High Starting Torque Motor with Full Overload Protection

- Solid State Circuitry with Power and Program Feedback LED’s

- On Board Open/Close/Stop buttons for service and adjustments

- Terminals labeled and grouped by function

- Auto-Detect monitored photo beam for simplified installation

- Selectable Operating modes B2, C2, D1, E2, T, TS

- Field adjustable built in functions including: timer to close, mid-stop, delay on reverse, lock bar sensing, maximum run time, etc.

- For Use on Sliding Doors

- Heavy Duty Worm Gear Reduction and Solenoid Brake

- Heavy Duty #41 Roller Chain Included

- Adjustable Torque Limiting Clutch

- Positive Chain Driven Rotary Limit Switches

- Manual Disconnect Arm for Operation of the Door in case of power failure

- Baked on Grey Powder Coat finish